The Ultimate Guide to Carbon Steel Rust Removal: Methods and Prevention

Carbon steel is a widely used material in various industries due to its strength and affordability. However, its high iron content makes it susceptible to rust, a common form of corrosion. Rust not only compromises the aesthetic appeal of carbon steel but also weakens its structural integrity. Understanding effective carbon steel rust removal methods and implementing preventive measures is crucial for maintaining the longevity and functionality of carbon steel components. This comprehensive guide will explore various techniques for carbon steel rust removal, from simple household remedies to more advanced industrial solutions. We will also delve into practical strategies to prevent rust formation, ensuring your carbon steel investments remain protected.

Understanding Rust Formation on Carbon Steel

Rust, chemically known as iron oxide, forms when iron reacts with oxygen in the presence of moisture. This electrochemical process results in the oxidation of iron, leading to the reddish-brown flaky layer we recognize as rust. Several factors can accelerate the rusting process, including humidity, exposure to salt, and the presence of acids or other corrosive substances. Recognizing these factors is the first step in effective carbon steel rust removal and prevention.

The Chemical Process of Rusting

The rusting process is an oxidation-reduction reaction. Iron atoms lose electrons (oxidation) and combine with oxygen atoms to form iron oxide. Water acts as an electrolyte, facilitating the transfer of electrons and accelerating the reaction. The presence of salt, especially sodium chloride, further enhances the conductivity of water, significantly speeding up the rusting process. Therefore, items exposed to saltwater environments are particularly vulnerable to rust.

Environmental Factors Contributing to Rust

Several environmental factors contribute to the formation of rust on carbon steel. High humidity levels provide the necessary moisture for the electrochemical reaction to occur. Exposure to acidic rain or industrial pollutants can also accelerate the corrosion process. Additionally, temperature fluctuations can create condensation, increasing the risk of rust formation. Understanding and controlling these environmental factors can minimize the need for frequent carbon steel rust removal.

Effective Methods for Carbon Steel Rust Removal

There are numerous methods available for carbon steel rust removal, ranging from DIY solutions to professional treatments. The best method depends on the extent of the rust, the size and shape of the object, and the desired outcome. Here, we will explore some of the most effective techniques.

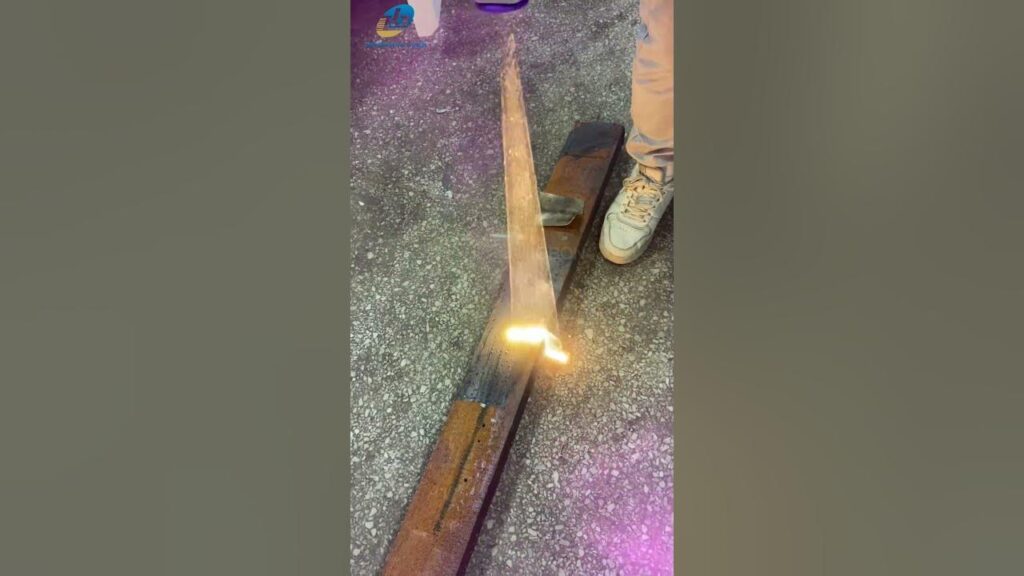

Mechanical Removal Techniques

Mechanical methods involve physically removing rust from the surface of the carbon steel. These techniques are often effective for removing heavy rust buildup and preparing the surface for further treatment. Common mechanical methods include:

- Wire Brushing: Using a wire brush to scrub away rust is a simple and effective method for small areas. Different types of wire brushes are available, including hand brushes and power drill attachments.

- Sanding: Sanding can be used to remove rust from larger surfaces. Start with a coarse grit sandpaper to remove the bulk of the rust, then gradually move to finer grits to smooth the surface.

- Grinding: Angle grinders equipped with abrasive discs are useful for removing heavy rust from large, flat surfaces. Exercise caution when using grinders to avoid damaging the underlying metal.

- Sandblasting: Sandblasting involves using compressed air to propel abrasive materials, such as sand or glass beads, against the rusted surface. This method is highly effective for removing rust from intricate shapes and hard-to-reach areas.

When using mechanical methods for carbon steel rust removal, always wear appropriate safety gear, including eye protection, gloves, and a dust mask.

Chemical Rust Removal Solutions

Chemical rust removers utilize chemical reactions to dissolve or loosen rust, making it easier to remove. These solutions are available in various forms, including liquids, gels, and pastes. Common chemical rust removers include:

- Phosphoric Acid: Phosphoric acid reacts with rust to form a protective phosphate coating, which inhibits further corrosion. It is commonly used in rust converters and metal conditioners.

- Oxalic Acid: Oxalic acid is a strong reducing agent that dissolves rust. It is often used to remove rust stains from fabrics and other materials, but it can also be effective for carbon steel rust removal.

- Hydrochloric Acid (Muriatic Acid): Hydrochloric acid is a powerful acid that can quickly dissolve rust. However, it is highly corrosive and should be used with extreme caution. Always dilute hydrochloric acid before use and wear appropriate protective gear.

- Citric Acid: Citric acid is a natural acid found in citrus fruits. It is a milder alternative to other chemical rust removers and is often used for removing light rust.

When using chemical rust removers, always follow the manufacturer’s instructions carefully and wear appropriate protective gear, including gloves, eye protection, and a respirator. Ensure proper ventilation to avoid inhaling harmful fumes. After applying the chemical rust remover, rinse the treated surface thoroughly with water and dry it completely.

DIY Rust Removal Remedies

For light rust or small areas, several DIY remedies can be effective for carbon steel rust removal. These remedies often utilize common household ingredients and are a cost-effective alternative to commercial rust removers.

- Vinegar: Vinegar contains acetic acid, which can dissolve rust. Soak the rusted object in vinegar for several hours or overnight, then scrub away the rust with a wire brush or scouring pad.

- Baking Soda: Baking soda is a mild abrasive that can help remove rust. Mix baking soda with water to form a paste, apply it to the rusted area, and scrub with a brush or cloth.

- Lemon Juice and Salt: The acidity of lemon juice combined with the abrasive properties of salt can help remove rust. Sprinkle salt on the rusted area, squeeze lemon juice over it, and scrub with a brush or cloth.

- Potato and Dish Soap: The oxalic acid in potatoes can help dissolve rust. Cut a potato in half, dip it in dish soap, and scrub the rusted area.

These DIY remedies are generally safe and easy to use. However, they may not be as effective for heavy rust buildup or large areas. [See also: DIY Metal Cleaning Solutions]

Preventing Rust Formation on Carbon Steel

Preventing rust formation is often more efficient and cost-effective than carbon steel rust removal. Implementing preventive measures can significantly extend the lifespan of carbon steel components and reduce maintenance requirements.

Protective Coatings

Applying protective coatings is one of the most effective ways to prevent rust on carbon steel. These coatings create a barrier between the steel and the environment, preventing moisture and oxygen from reaching the surface. Common protective coatings include:

- Paint: Painting carbon steel provides a durable and aesthetically pleasing protective layer. Choose a paint specifically designed for metal surfaces and apply multiple coats for optimal protection.

- Powder Coating: Powder coating involves applying a dry powder electrostatically to the carbon steel surface, then curing it with heat to create a durable and corrosion-resistant finish.

- Galvanizing: Galvanizing involves coating carbon steel with a layer of zinc, which provides sacrificial protection. Zinc corrodes preferentially to iron, protecting the underlying steel even if the coating is scratched or damaged.

- Oil and Grease: Applying a thin layer of oil or grease can protect carbon steel from rust, especially for parts that are stored or used in harsh environments.

Surface Preparation

Proper surface preparation is crucial for the effectiveness of protective coatings. Before applying any coating, ensure the carbon steel surface is clean, dry, and free of rust, dirt, and grease. Use a wire brush, sandpaper, or chemical cleaner to prepare the surface. [See also: Best Practices for Metal Surface Preparation]

Controlling Environmental Factors

Controlling environmental factors, such as humidity and exposure to corrosive substances, can also help prevent rust formation. Consider the following measures:

- Store carbon steel items in a dry, well-ventilated area.

- Avoid exposing carbon steel to salt, acids, and other corrosive substances.

- Apply rust inhibitors or corrosion inhibitors to protect carbon steel in harsh environments.

- Regularly inspect carbon steel components for signs of rust and address any issues promptly.

Choosing the Right Rust Removal Method

Selecting the appropriate carbon steel rust removal method depends on several factors, including the severity of the rust, the size and shape of the object, and the available resources. Consider the following guidelines:

- For light surface rust, DIY remedies like vinegar or baking soda may be sufficient.

- For moderate rust buildup, mechanical methods like wire brushing or sanding may be necessary.

- For heavy rust or intricate shapes, chemical rust removers or sandblasting may be required.

- Always prioritize safety and wear appropriate protective gear when using any rust removal method.

Conclusion

Carbon steel rust removal is an essential task for maintaining the integrity and longevity of carbon steel components. By understanding the causes of rust formation, implementing effective removal methods, and adopting preventive measures, you can protect your carbon steel investments and ensure they remain in optimal condition. Whether you choose mechanical methods, chemical solutions, or DIY remedies, remember to prioritize safety and follow best practices for surface preparation and coating application. Investing in rust prevention is an investment in the long-term durability and performance of your carbon steel assets. [See also: Advanced Corrosion Prevention Techniques]